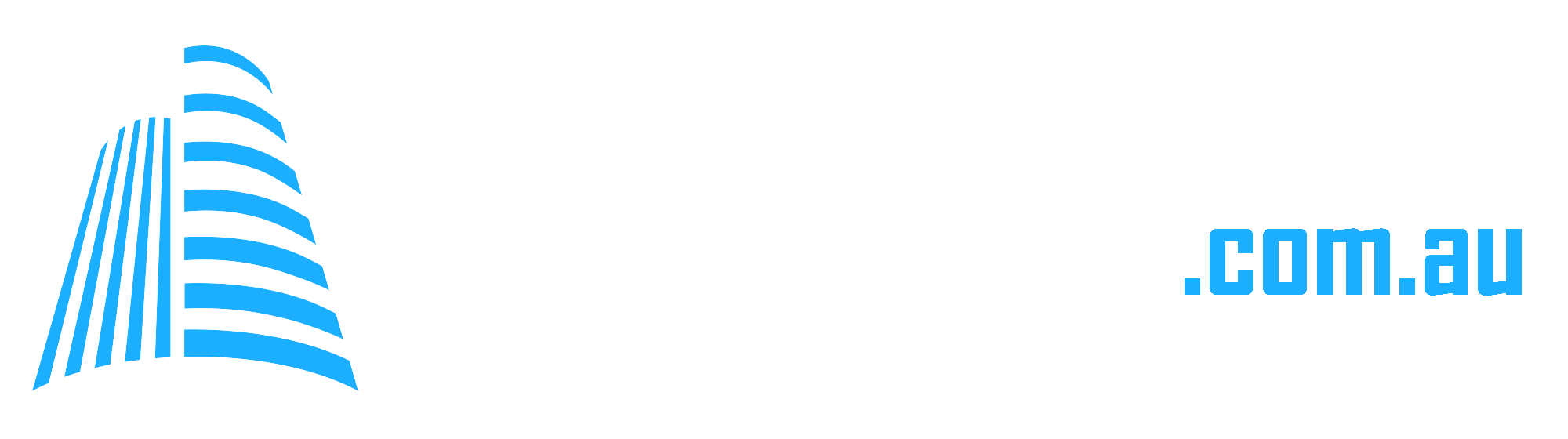

Concrete is generally fully hydrated at about 25% water:cement ratio. But that needs to be water available to the cement. In practice a significant amount of water is absorbed in wetting the surface of gravel & sand. So the water content is increased to about equal, by mass, to the cement content.

This assumption that more water is needed to account for that absorbed by the the non-cement components can go wrong if the other items are already damp or wet, for example, from overnight rain onto the stockpile of aggregate & sand. Good batching plants take wetness of aggregate & sand into account, but bad ones may not, leading to too high a slump, and weakened concrete.

So far as we are concerned on a daily practical basis, to improve strength, durability, and performance in general: Slump needs to be minimized. Entrained air should be expelled (vibrate). The concrete kept cool & damp while curing (pond).

Slump

Assuming that the concrete supplier has provided the right specifications. As the slump increases, the strength is reduced, the porosity is increased, and shrinkage cracking is increased.

Unfortunately, standard slump from some suppliers is now 100. But other slumps (preferably lower) can be specified, but may be ignored by the supplier. I’ve known design slump values to be ignored, and slumps as high as 140 to be delivered (by well known national companies). You may not even be present when such a slump is delivered, and it may be denied later.

But assuming that they will deliver the design slump, then for critical use, such as suspended slabs, polished concrete, and corrosive environments, the ideal design slump should be about 60. That is too low for workability, and there’s a risk that the concreter will stick a hose pipe into the truck. So the slump is specified as 60 brought up to 100 by superplaticizer Adva 145 (or similar modern additives). That tells the supplier to produce a concrete mix with 60 native slump but add sufficient superplasticizer to improve workability to 100 slump. Modern plasticizers have no significant deleterious effect on concrete, if used in moderation, and a can is carried in the truck to add at the work site, if the slump is still too stiff. If the concrete has a long way to travel, and may begin to ‘go off’, then a little retarder should be added at the yard.

Of course, it is possible to have high slump, due to excessive water, and maintain 28 day strength by adding more cement into the mix. But this also increases the shrinkage & cracking rate (as well as cost), since they are directly proportional to the cement content as well as the water ratio. So it is best to use low slump & increase it only with superplasticizer, such as 60 brought up to max 100 with superplasticizer.

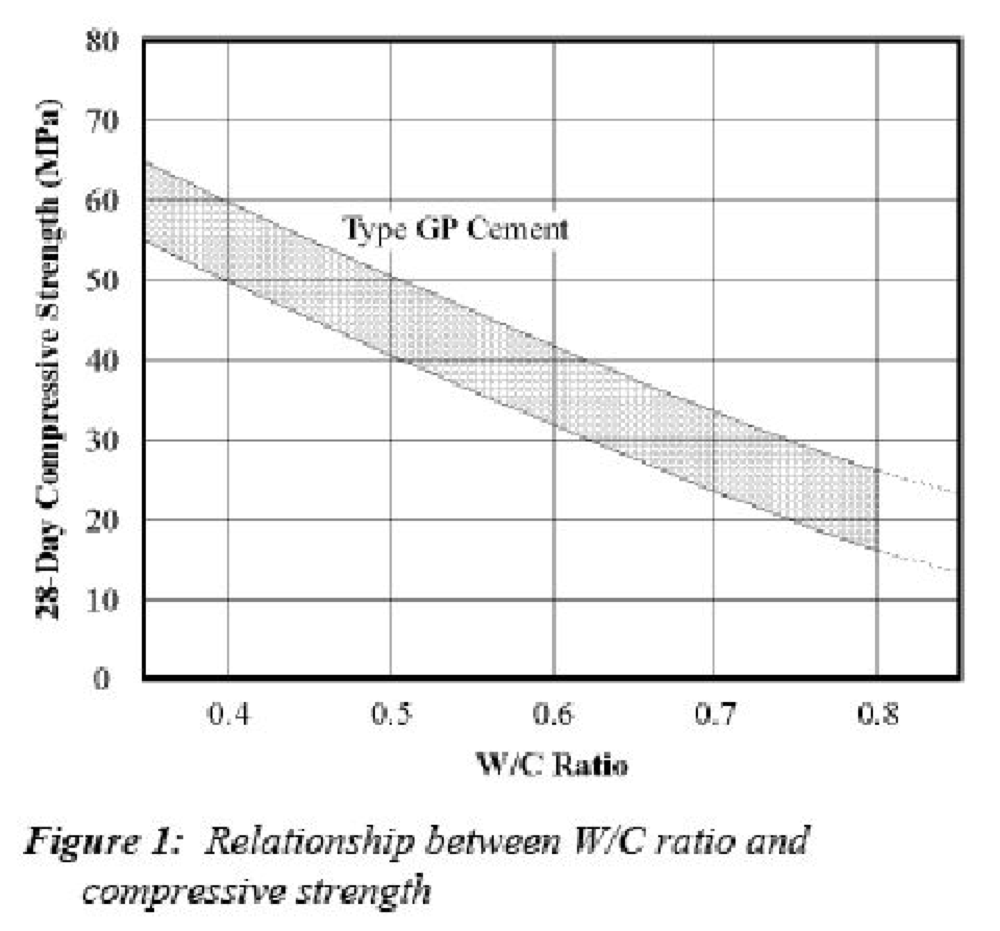

Vibration

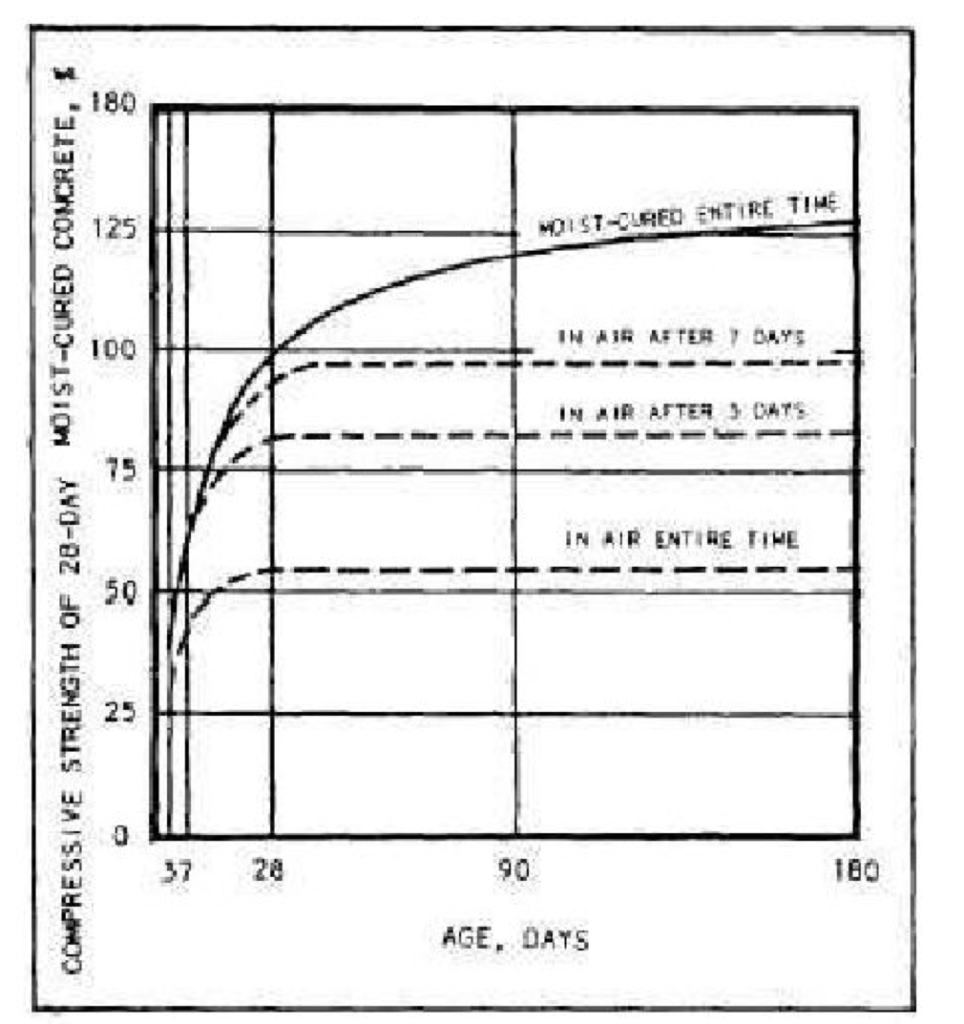

As the concrete is tumbled in the cement truck, and as it is poured out, it is full of air bubbles, which due to surface tension are reluctant to simply rise & escape at the top. Strength, durability, and workability are significantly increased, even with shallow slabs, if a vibrator is used (see graph). There are some excellent models now sold, with little engines or even electric motors, that look like a whipper-snipper. They don’t have a compressed air umbilical to drag around, are light (even carried in a backpack) and easy to operate. Concreters should start getting into the habit of using them, and I think they’ll be fashionable in a few years for everything from strip footings to ground slabs. (Remember, in the past it was standard practice to pull up mesh with a hook. Now we almost always use chairs).

Vibration also improves adhesion of the concrete to the reinforcement, because any loose dust on the reo bars is shaken off into the concrete as it scours the surface of the steel.

Vibration encourages concrete to fill all nooks & crannies, improving surface finish against formwork.

Furthermore, vibration reduces the occurrence of hairline cracks by reducing the stress points caused at strings of bubbles which become a weak fracture line. (uniform, deliberate air entrainment is more controlled & has specific uses)

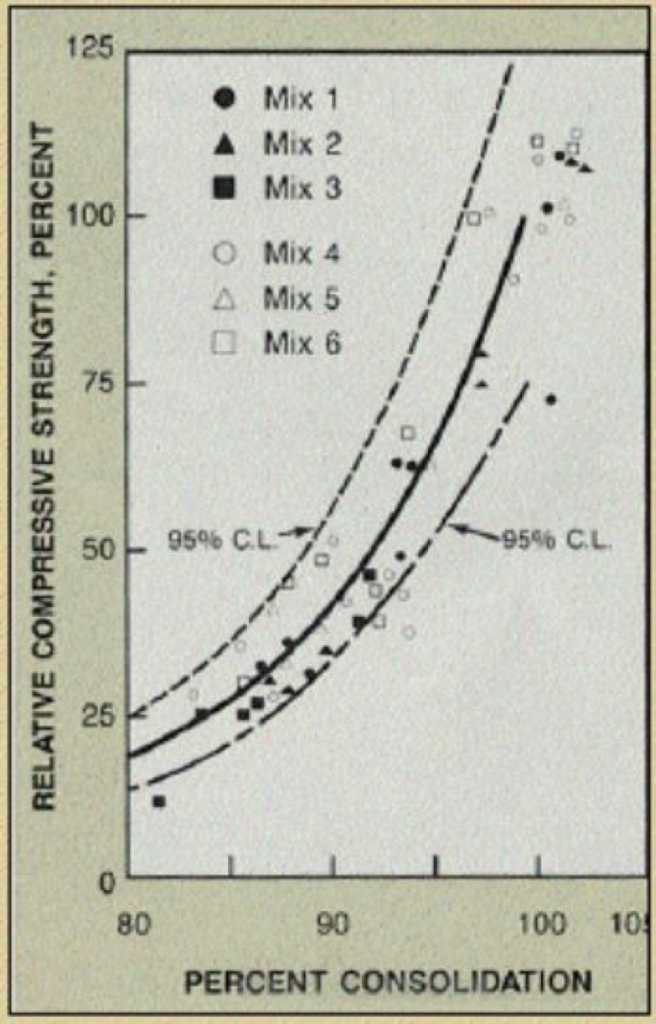

Cooling & keeping damp

This is a a special problem for Australia. Particularly ground slabs poured in the summer, which are badly affected by over-heating: The ground they are poured on was already warm. They are at ground level sheltered from the breeze. The Sun blazes down on them through the day.

Thus the concrete cures too fast, and also unevenly; with pockets of dehydration. Surface crazy cracking is often the result. The concrete should be kept damp & cool for at least the first few days after the pour (see graph).

Sprinklers are no use; the spray is blown willy nilly. Sealing the surface with something such as a silicon spray is only a partial problem; it stops/reduces evaporation, but if anything, increases the heating of the slab, often bringing the temperature to close to boiling point. (Note; this is a different situation from autoclaving, which is used in controlled conditions for rapid, even, humid curing).

The only satisfactory way of keeping a ground slab both cool and damp is by using a small bund all around the edge & ponding with a few centimetres of water (see graph). For best results, this can be done once the slab is sprayed with silicon sealant.

By & By:

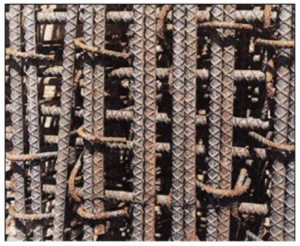

But nothing will save you if you don’t use enough steel, as in the photo below:

How many design errors can you spot in the above photo?

(I think the ‘engineer’ had shares in a steel company, eh? 😉

Author: Sam Nejad